- Specifications

- Configuration Table

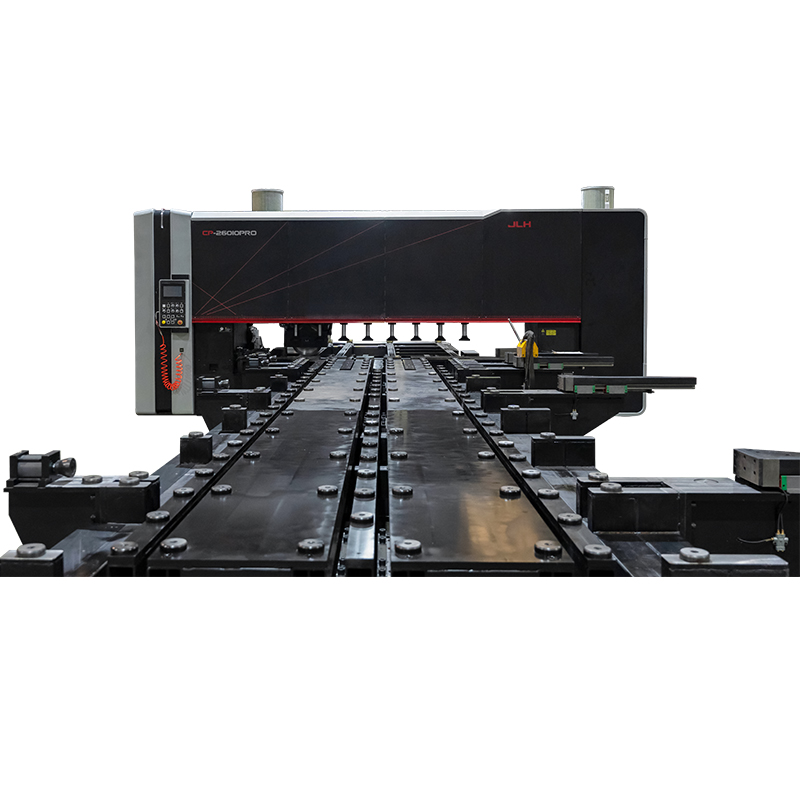

| Specifications | CP-26010PRO |

| Cutting range square (W x H) | 2600*100mm 102*4in |

| Shortest length of cut-off piece | 1100*20m 43.3*0.8in |

| Shortest remnant length in automatic operation, possible only if the material has a perfect geometric surface | 400mm /15.7in |

Shortest remnant length individual cut | 40mm /1.6in |

| Length | 10030mm/394.9in |

| Width incl. chip conveyor | 6300mm/248in |

| Height | 3000mm/118.1in |

Material support height | 720mm/8.4in |

| Total weight | ≈28000KG/61729lb |

| Total connected load | 41kw/54.6hp |

| Power of saw motor | 30kw/40hp |

| Hydraulic motor | 7.5kw/10hp |

| Cutting speed infinitely variable with | 40-100rpm/min |

| Saw feed speed | 1 - 700 mm/min 0.04-27In/min |

| Automatic material feed length, single stroke | 800mm /31.5in |

| Automatic material feed length, multiple stroke | 9999mm /393.66in |

| Saw blade diameter | φ425mm /φ16.73 |

| Saw blade bores | φ50mm /φ1.96 |

| Saw blade thickness | 2.7mm*2.25mm 0.1in*0.08in |

| Functional description | CP-26010PRO |

CE standard fully enclosed protection | ● |

| 0 degree servo feed | ● |

| JLH-EHA | ○ |

| Saw Master | ○ |

| CE Electrical Safety | ● |

UL Electrical Safety | ○ |

Main drive servo motor | ● |

| HMI+Buttons | ● |

| Inverter | ● |

| Mistspray system (2L) | ● |

| Dust collection device | ● |

| Cutting pipe blast device | × |

| Cabinet air conditioner | ● |

| LED working light | ● |

| Automatic chip conveyor (spiral) | ● |

| Vise pressure regulator | ○ |

| Top clamp | ● |

| Hydraulic cooling fan | ● |

| Auto Lubrication device | ○ |

| Roller type work table | ● |

| Servo Feed | ● |

| Units: mm/kw/L/m/min | ● |

| Sawdust collection Cart 70 (L) | ● |

| Tool box (wire brush, levelling pads, spare paint) | ● |

| Saw blade | ● |

| Transport underframe for containers | ○ |

| ● : Standard ○ : 0ptional × : Non-optional | |